One out of every million people in the world suffers from an allergy caused by metals. The most common metal that causes allergies is nickel. Once allergies occur, it can lead to symptoms of contact dermatitis,such as redness, itching, and oozing of yellow fluid from the surrounding skin. These are all adverse reactions caused by the release of metal ions. Once metal allergic dermatitis occurs, the most fundamental and effective way to deal with nickel allergy is to isolate the allergen.

Nickel is contained in many alloy products in daily life. Such as coins, various alloy products, electroplated objects, glasses frames, metal watch straps, belt buckles, artificial jewelry, underwear hooks, etc. Direct contact with the skin will cause allergic reactions to sensitive individuals.

Although many items contain nickel, it must be in the form of nickel ions in a solution, such as sweat, in order to be absorbed by the skin or body. If sufficient nickel ions are absorbed by the skin (from wear and corrosion of nickel-containing materials), it may cause sensitization in non-nickel-allergic individuals, or elicit a dermatitis reaction in nickel-allergic individuals. The main factors affecting metal release are the corrosion resistance of the material, and whether the item is in a scenario where it is easily worn.

Therefore, the key factor in evaluating the risk of nickel allergy is the amount of nickel released, not the amount of nickel contained. There are some nickel-containing materials, such as watches made of stainless steel containing 9-28% nickel, have not been reported to cause allergic reactions to nickel. This was shown by the 2004 revision of the EU Nickel Directive, which restricted the release of nickel rather than the amount of nickel for all uses.

Due to some individuals are allergic to nickel, both the EU and China have made regulations on the amount and release of nickel in products that come into long-term contact with human skin and products that pierce ears or other parts of the body: the European Union has made regulations to unify the laws of each member state Passed the nickel control directive 94/27/EC, which is used to control the amount of nickel used in products that have direct or long-term contact with the skin. In 2004, the European Union passed the EC directive. For all punctured Objects have been revised and implemented since September 2005. EC no longer requires the total content of nickel in accessories that pierce ears or other parts of the body, but requires that the release of nickel must not exceed 0.2ug/cm2/week.

Nickel release detection principle: place the test object in artificial sweat testing solution for one week, and use atomic absorption spectrometry, inductively coupled plasma mass spectrometry or other suitable analysis methods to test the concentration of nickel (Ni) dissolved in the solution. The amount of nickel release is expressed in micrograms per square centimeter per week (μg/cm²/week).

At present, customers from TWS, smart wear and other industries have a feature of the product, that is, it is applied to the human body andin close contact with the skin. At this time, due to the problem of nickel plating, when the product comes into contact with the human skin, nickel ions will be released through sweat or other methods, causing skin allergies and seriously affecting people's health.

HYP has many customers from the smart wear industry who are allergic to nickel in products. Some customers have knowledge or experience in this area and will request that the products not contain nickel. There are also some customers who have no experience in this field, and sometimes do not tell us where the product is applied based on the confidentiality requirements of product development, which leads to deviations when we recommend product material coatings, which will have time and cost impacts on both customers and HYP.

According to the requirements of current market products, HYP specially introduces a special coating - copper-tin zinc ternary alloy, also known as nickel replacement, white copper tin, refers to the plating technology covered with "copper-tin zinc ternary alloy". Among them, "Ternary alloy" refers to the alloy of copper, tin and zinc, accounting for 55% of copper, 25-30% of tin and 15-20% of zinc. "Ternary alloy" appearance and stainless steel is similar, because it does not contain nickel elements, so there will be no nickel ion precipitation affect the health of the human body, is a very good nickel generation products.

Related news

-

Common items and methods for precision metal plating testing

Electroplatingisacommonmetalsurfacetreatmentsolution.Electroplatingcannotonlyincreasetheappearanceoftheproduct,butalsoimprovethepe... -

Key points of electroplating of pogo pin parts in precision electronic connector electroplating

Pogopin is a common electronic connector. Due to its size and precision, it is generally processed by roll plating. The following is the key points of electroplating from the three parts of pogopin: spring, barrel and plunger: -

Advantages and disadvantages of common electroplating layers in medical microneedle electroplating

Due to the wide application and particularity of medical microneedles, the electroplating layer of medical microneedles plays an important role in their application. The following introduces the common electroplating layers of medical microneedle electroplating processing. -

Plating Principles and Classification

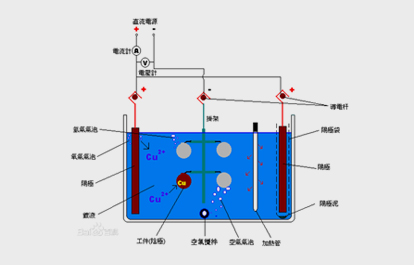

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent metal oxidation ( Such as rust), improve wear resistance, conductivity, reflectivity, corrosion resistance and... -

Wastewater Treatment at HYP

Electroplating enterprises and surface treatment enterprises have chemical oxidation, anodic oxidation, galvanizing, zinc-nickel alloy plating, chrome plating, copper plating, gold plating, nickel plating, silver plating and other plating types, and the wastewater produced is very messy.